CÔNG TY TNHH XNK CÔNG NGHIỆP DONG RUI VIỆT NAM

Nhà sản xuất mút xốp PE – EPE hàng đầu

Thành lập từ tháng 6 năm 2023 tại Bắc Ninh, Việt Nam, Công ty TNHH XNK Công nghiệp Dong Rui Việt Nam tự hào là nhà cung cấp hàng đầu các giải pháp đóng gói chất lượng cao. Chúng tôi chuyên sản xuất và phân phối đa dạng các sản phẩm Mút Xốp EPE Foam, bao bì vỉ và túi PE, đáp ứng nhu cầu đóng gói đa năng cho nhiều ngành công nghiệp.

Dong Rui Việt Nam tích hợp dịch vụ thiết kế chuyên biệt, quy trình sản xuất hiện đại và chính sách hậu mãi tận tâm, cam kết mang đến bao bì chất lượng vượt trội, thân thiện với môi trường. Với cơ sở vật chất tiên tiến và đội ngũ chuyên gia giàu kinh nghiệm, chúng tôi không ngừng đổi mới, tối ưu hiệu quả và hướng đến mục tiêu trở thành đối tác đóng gói toàn cầu đáng tin cậy cho mọi doanh nghiệp.

SẢN PHẨM BÁN CHẠY

DANH MỤC SẢN PHẨM

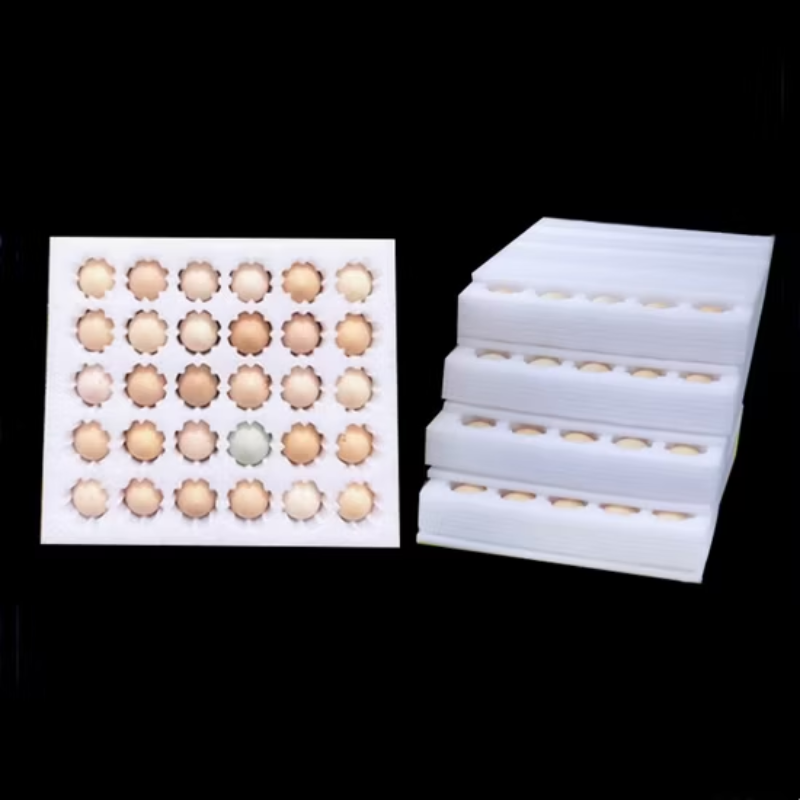

TUỲ CHỈNH MÚT XỐP EPE THEO YÊU CẦU

Dong Rui Việt Nam cung cấp cho bạn các giải pháp đóng gói mút xốp PE Foam tùy chỉnh, được thiết kế để đáp ứng nhu cầu bảo vệ sản phẩm của bạn. Thông qua các vật liệu thân thiện với môi trường chất lượng cao, quy trình sản xuất tiên tiến và dịch vụ tùy chỉnh chuyên nghiệp. Chúng tôi đảm bảo rằng mọi gói hàng đều có thể mang lại trải nghiệm người dùng an toàn và thoải mái nhất cho sản phẩm của bạn. Hãy chọn chúng tôi để làm cho sản phẩm của bạn nổi bật và nâng cao giá trị thương hiệu của bạn.

QUY TRÌNH SẢN XUẤT XỐP EPE

- Tuyển chọn và tiền xử lý nguyên liệu: Lựa chọn kỹ lưỡng các hạt nhựa PE chất lượng cao. Sau đó, các hạt PE được gia nhiệt sơ bộ để đảm bảo hiệu quả tối ưu trong quá trình xử lý tiếp theo.

- Giai đoạn tạo bọt tiên tiến: Dưới tác động của nhiệt độ và áp suất trong môi trường kiểm soát, các hạt PE trương nở, kết hợp cùng chất tạo bọt đặc biệt tạo ra bọt EPE có cấu trúc đồng đều và độ đàn hồi vượt trội.

- Định hình và gia công theo yêu cầu: Bọt EPE được đúc thành tấm hoặc cuộn lớn, sau đó cắt và tạo hình theo kích thước và quy cách khách hàng yêu cầu.

- Làm mát và ổn định cấu trúc: Bọt EPE trải qua quá trình làm mát để đảm bảo độ bền và duy trì hình dạng tối ưu cho các công đoạn tiếp theo.

- Kiểm soát chất lượng và đóng gói chuyên nghiệp: Mọi sản phẩm đều được kiểm tra chất lượng nghiêm ngặt và đóng gói cẩn thận theo tiêu chuẩn trước khi xuất xưởng.

GIẢI PHÁP BẢO VỆ TỐI ƯU CHO SẢN PHẨM

Xốp EPE Foam với:

- Đặc tính vượt trội: Với cấu tạo từ nhựa PE kết hợp khí, mút xốp PE Foam sở hữu trọng lượng nhẹ, độ bền bỉ và khả năng chịu lực ấn tượng, đảm bảo an toàn cho hàng hoá của bạn.

- Cấu trúc thông minh, đa năng: Thiết kế ô hở độc đáo, không chỉ tăng cường khả năng thoáng khí mà còn giảm thiểu tác động từ các yếu tố bên ngoài, bảo vệ sản phẩm khỏi ẩm mốc và va đập.

- Ứng dụng rộng rãi: Là lựa chọn lý tưởng trong ngành đóng gói, cách nhiệt và bảo vệ sản phẩm trong quá trình vận chuyển, giúp giảm thiểu rủi ro hư hỏng và tối ưu chi phí.

- Ưu điểm nổi bật: Khả năng chống va đập tuyệt vời là yếu tố then chốt giúp bảo vệ sản phẩm nguyên vẹn trong mọi điều kiện.

TẠI SAO NÊN CHỌN XỐP EPE DONG RUI VIỆT NAM?

Sản phẩm chất lượng cao

Xốp EPE Foam của Dong Rui được sản xuất từ nguyên liệu chất lượng cao, đảm bảo chất lượng ổn định. Sản phẩm có khả năng chịu nén, đệm và chống sốc tốt, được sử dụng rộng rãi trong đóng gói và bảo vệ.

Cung cấp giải pháp phù hợp

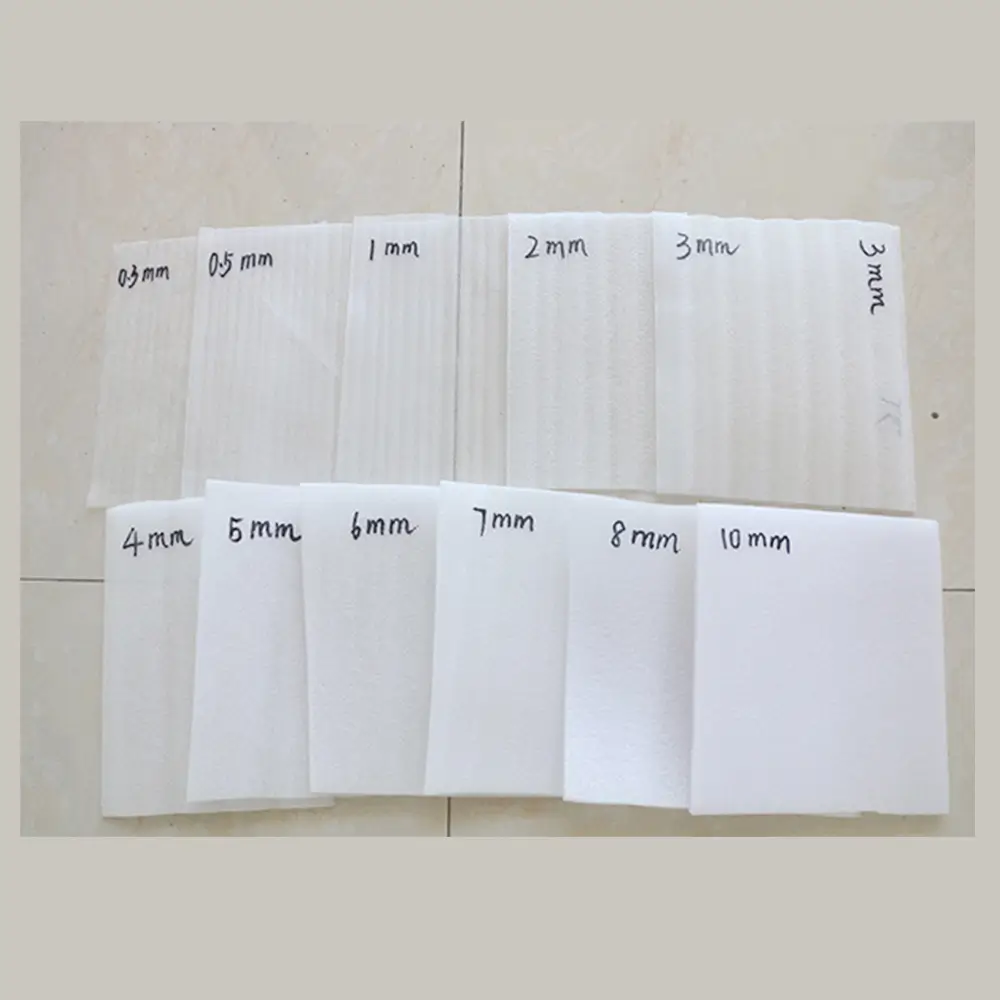

Dong Rui cung cấp nhiều lựa chọn về độ dày, độ dài và thiết kế theo hình dạng phù hợp với bạn. Dù số lượng lớn hay tùy chỉnh theo lô nhỏ, công ty đều đáp ứng nhu cầu của khách hàng.

Kinh nghiệm sản xuất

Dong Rui đã tích lũy nhiều năm kinh nghiệm trong ngành tại thị trường Trung Quốc và giờ đây mong muốn được phát triển tại Việt Nam. Vậy nên có thể cung cấp dịch vụ tư vấn để giúp bạn chọn giải pháp đóng gói và vật liệu phù hợp nhất.

Nguồn cung ổn định

Dong Rui Việt Nam có năng lực sản xuất mạnh mẽ và hệ thống chuỗi cung ứng hoàn chỉnh, đảm bảo giao hàng đúng hạn, tránh thiếu hụt vật liệu ảnh hưởng sản xuất.

DỊCH VỤ HẬU MÃI 24/7

Dong Rui Việt Nam – Cam kết dịch vụ tận tâm, đồng hành cùng bạn:

- Phản hồi tức thì, hỗ trợ 24/7:

Chúng tôi luôn sẵn sàng hỗ trợ khách hàng trực tuyến 24 giờ mỗi ngày, đảm bảo mọi thắc mắc và vấn đề được giải quyết nhanh chóng, không gián đoạn.

- Hỗ trợ kỹ thuật chuyên nghiệp:

Đội ngũ kỹ thuật giàu kinh nghiệp của chúng tôi cung cấp hướng dẫn toàn diện về lắp đặt, sử dụng và bảo trì sản phẩm, giúp bạn hoàn toàn yên tâm trong suốt quá trình sử dụng.

- Đảm bảo chất lượng tuyệt đối:

Chúng tôi cam kết về chất lượng sản phẩm. Trong trường hợp phát sinh lỗi từ nhà sản xuất, dịch vụ đổi trả miễn phí của chúng tôi sẽ bảo vệ tối đa quyền lợi của bạn.

- Quan tâm và đồng hành thường xuyên:

Chúng tôi chủ động liên hệ, lắng nghe phản hồi và thấu hiểu nhu cầu của khách hàng. Từ đó, Dong Rui Việt Nam không ngừng cải tiến sản phẩm và dịch vụ để mang đến sự hài lòng cao nhất.

ĐỐI TÁC CỦA CHÚNG TÔI

CÂU HỎI THƯỜNG GẶP (Q&A)

Expanded Polyethylene Foam is a soft, lightweight, impact-resistant and vibration-proof packaging material made of Polyethylene (PE) foam. Its main characteristics are good cushioning and compression resistance, widely used in the packaging of electronic products, fragile goods, etc.

PE Foam has the following significant advantages:

- Đệm và chống sốc tốt, bảo vệ đồ vật khỏi bị hư hại

- Nhẹ và dễ vận hành, giảm chi phí vận chuyển

- Thân thiện với môi trường và có thể tái chế, đáp ứng nhu cầu phát triển bền vững hiện đại

- Chống thấm nước, chống ẩm, chống tĩnh điện, phù hợp với nhiều nhu cầu đóng gói khác nhau

Expanded Polyethylene Foam is different from traditional foam plastics (such as polystyrene foam) in structure and performance. Expanded Polyethylene Foam has a tighter and more uniform structure, which can provide better impact resistance and cushioning performance. At the same time, it is more environmentally friendly and recyclable than traditional foam.

Expanded polyethylene foam is widely used in electronic products, household appliances, glass products, ceramics, cosmetics and other fields. It is especially suitable for packaging fragile goods that need protection. It is also suitable for protective packaging of bulk goods such as furniture, electrical appliances and mechanical appliances.

The load-bearing capacity of expanded polyethylene foam depends on its density and thickness. In general, expanded polyethylene foam is suitable for packaging light to medium weight items. For items that are overweight or have special needs, it may be necessary to provide adequate protection by adding thicker or multi-layer packaging.

Expanded Polyethylene Foam is a recyclable and environmentally friendly material and can be sent to professional recycling stations for disposal after disposal. Since it does not emit toxic substances, Expanded Polyethylene Foam is a more environmentally friendly choice than other packaging materials. Companies or individuals can minimize their impact on the environment through recycling or incineration systems.